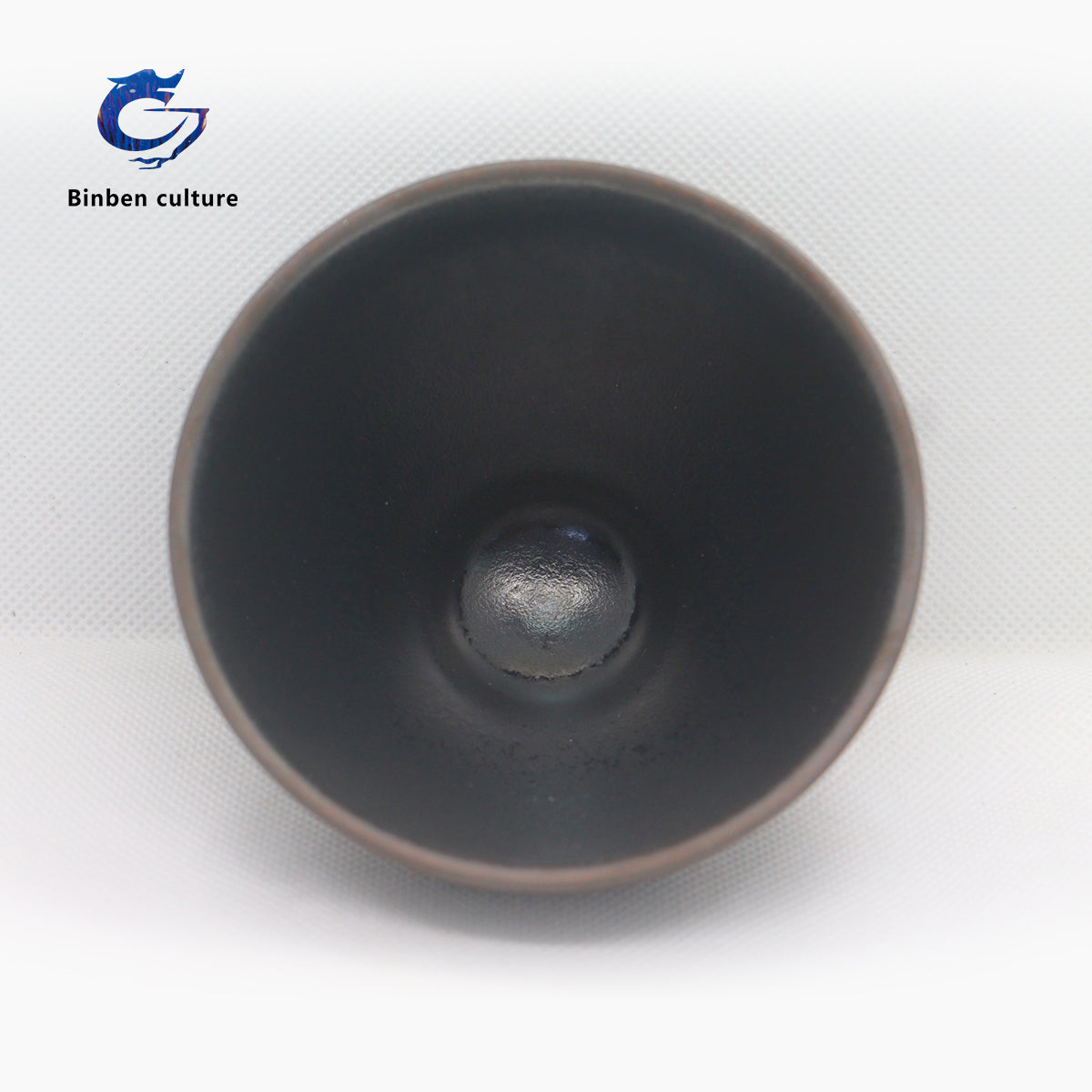

Chen Yuan Fujian Cup Ware Type: Bundle Mouth Glazed Surface: Gray Shell

Chen Yuan Fujian Cup Ware Type: Bundle Mouth Glazed Surface: Gray Shell

Impossibile caricare la disponibilità di ritiro

Chen Yuanfu, born in 1972, is a veteran artist of Jianzhan under the tutelage of Xu family. Fujian Province Arts and Crafts Celebrity, Ceramic Arts and Crafts Master, First Wuyi Craftsman Celebrity, Folk Arts and Crafts Famous Artist. After graduating in 2015, he independently founded Far Fujian Zhan Ceramics Co., Ltd. Far Fujian Zhan is a new type of workshop wood fired sauce glazed bundle mouth lamp that integrates research and development, production, sales, and experience. On August 6, 2017, it was collected by Jianyang District Museum; On March 15, 2018, Biankou Oil Drop Jianzhan was collected by the Chinese Academy of Painting and Calligraphy and received high praise; On March 26, 2018, the bowl shaped oil droplet was collected by the Japanese Tao Yun Culture Development Collection; In June 2018, the Deep Sea Bundle Mouth Lamp won a gold medal and other awards in the Excellent Works Competition of the 3rd Hefei Tea Purple Clay Pot Ceramic Crafts Expo in China

Notice: Due to the transmutation in kiln, the pattern on each teaware will be slightly different. Therefore, every Jian zhan Tenmoku is unique and special, but it will be remained generally the same.

Visualizza dettagli completi

1. Clay selection. Jian Zhan's glaze and clay need to have a high iron content. Other kilns in the Song Dynasty tried to imitate Jian Zhan. Still, they usually could not succeed for the minerals in their geographic location could hardly meet the standards of making a Jian Zhan.

2. Crushing. Place the prepared clay and glaze in a machine for pulverization

3. Washing and sieve. The thickness of the clay or glaze should be moderate. After sieving, the clay needs to be put into the slurry tank, while the glaze needs to be placed in the glaze pool.

4. Chen Fu, which is a ceramic terminology, refers to placing the clay in a room away from sunlight and air, keeping a certain temperature and humidity, and storing it for a while.

5. Knead the clay. This process is aimed to further remove the air and impurities in the clay, make the mud dense, uniform humidity, and facilitate forming, meanwhile, it also prevents the clay from drying and cracking during post-production.

6. Shaping, is usually divided into hand shaping and machine shaping.

7. Modification. The traditional shape of Jian Zhan is mainly a shallow circle foot, and the base part and the “inner ring ” of the foot need to be modified by a knife.

8. Kiln the unglazed Jian Zhan. This process can increase the mechanical strength of the clay, and also remove a part of the cracked and fragile Jian Zhan in advance.

9. Blend glaze. The glaze formula of the ancient method is to use natural iron ore glaze and plant ash. These two simple substances can compose a beautiful glaze, which looks incredible, but the craft of making Jian Zhan is to use the simplest materials to create the most mysterious crystals.

10. Glazed. One of the big features of Jian Zhan's crafting is the half-glazed. Ancient people would specially design a glaze line to facilitate the control of the glaze range. Glazing also needs very skillful technique, ensure the glaze is moderate. If thin, the room for the growth of the crystal is too small to produce delicate works; if too thick, the glaze may easily stick to the bottom.

11. Put into the kiln. There is usually a need to place a layer of alumina powder on the bottom to avoid sticking.

12. Kiln and fire the Jian Zhan. The kiln is the most important process of making Jian Zhan. If the time, degree, and frequency of reduction are not well mastered, the desired glaze color will not be successfully created. After being put into the kiln, the master must concentrate on controlling the degree of reduction and not leave it for a long time.

13. Finishing kiln. After the kiln, due to various restrictions on the making process, each kiln will inevitably produce defective products, which must be disposed of on-site. Products that pass the quality inspection can be sold.

About BinBen Culture

At Binben Culture, we preserve the centuries-old legacy of Chinese ceramic mastery, blending time-honored techniques with modern design to create exquisite porcelain that elevates everyday life with artistry, quality, and cultural essence.

Featured collection

-

Xu Guozhu Dragon Kiln Wood-fired Jianzhan Master Cup Tea Cup Tea House Tianmu Cup Pure Handmade Tea Cup

Prezzo di listino $499.00 USDPrezzo di listino -

Fujian Jianyang Jianzhan tea cup partridge spot original ore owner

Prezzo di listino $469.00 USDPrezzo di listino -

Dangerous wood-fired Jianzhan pure handmade tea cup gold thread large tea cup host cup high-end collection single cup

Prezzo di listino $1,900.00 USDPrezzo di listino -

Jianzhan fine tea set Li Ximei pearl spot oil drop host cup Jianyang Jianzhan host cup

Prezzo di listino $999.00 USDPrezzo di listino

BinBen Culture

Seven Jian Zhan 07 31

Share